Pinch Type Solenoid Valve Dealer

Introduction

Established in 2005, Ammar Industrial Corporation is an authorized supplier, wholesaler, dealer, stockist, distributor, and retailer of precision-engineered pneumatic-hydraulic-instrumentation-automation products and industrial process equipment based in Kolkata. Our range includes Air Preparation Unit, Pneumatic Solenoid Valve, Pneumatic Cylinder Actuator, hydraulic tools, fluid automation solenoid valves, etc. Our quality norms enable us to maintain and enhance our position in today’s competitive market. Ammar Industrial Corporation’s premium quality products are recognized as the most reliable firm. Moreover, we follow a quality policy to monitor these products before delivering them to customers.

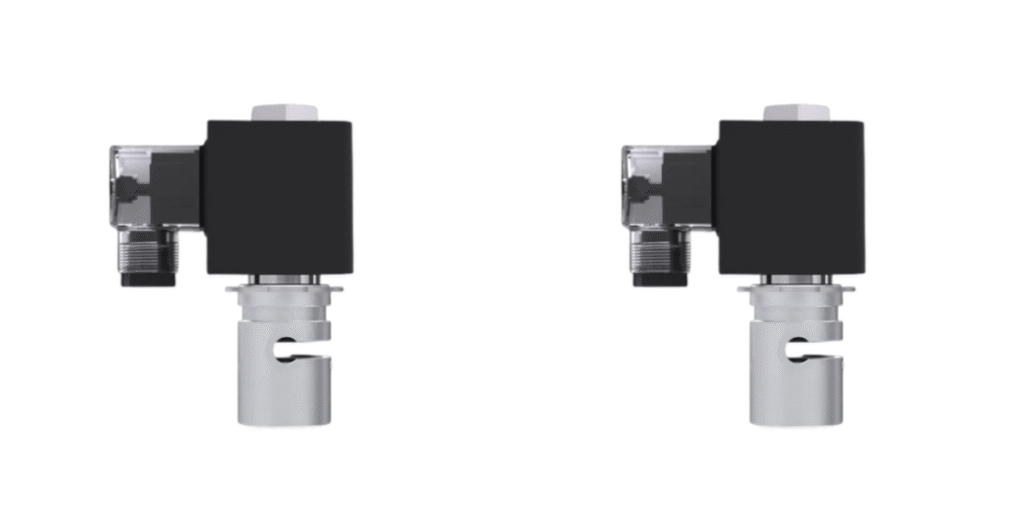

A special kind of valve called a pinch type solenoid valve regulates fluid flow by “pinching” a flexible tube. Unlike conventional valves, which have moving elements that might clog or wear out, this design is straightforward but incredibly efficient. It is made out of an electromagnet called a solenoid, which, when activated, drives a plunger to compress or “pinch” a tube, halting the flow. We are the best Pinch Type Solenoid Valve Supplier.

De-energizing the solenoid causes the tube to revert to its initial shape, which permits unrestricted fluid flow.This design’s simplicity makes it a popular option for many different sectors. There is no chance that the fluid will become contaminated by the interior parts of the valve because it only comes into touch with the flexible tube’s inner surface. Because of this, it is ideal for uses involving corrosive or sterile media.

What Is a Pinch Type Solenoid Valve

A special kind of valve called a pinch type solenoid valve regulates fluid flow by pinching a flexible tube. Unlike conventional valves, which have moving elements that might clog or wear out, this design is straightforward but incredibly efficient. It is made out of an electromagnet called a solenoid, which, when activated, drives a plunger to compress or pinch a tube, halting the flow. De-energizing the solenoid causes the tube to revert to its initial shape, which permits unrestricted fluid flow. We are the best Pinch Type Solenoid Valve Provider.

Why Choose Ammar Industrial Corporation

- Expert Advice and Knowledge: We don’t think there is a one-size-fits-all solution. Our team of seasoned experts is well-versed in fluid automation, hydraulic, and pneumatic systems. In order to assist you choose the ideal pinch valve, we take the time to listen to your unique application requirements and provide professional guidance while taking cycle life, temperature, pressure, and fluid type into account.

- Unwavering Commitment to Quality: The caliber of our products is the foundation of our reputation. Our pinch type solenoid valves are sourced from top manufacturers who are renowned for their dependability and robustness. To guarantee that it satisfies the highest industry requirements, each valve in our inventory is subjected to stringent quality checks. You are investing in a reliable product when you purchase from us.

- Extensive Product Offering: We recognize that each application is unique. A large range of pinch type solenoid valves in various sizes, materials, and configurations normally open, normally closed, and three way are available in our inventory. This wide range guarantees that we can offer a solution for practically every requirement, from a tough industrial operation to a sensitive lab device.

- Outstanding Customer Service: After the sale, our relationship with you continues. We take great satisfaction in providing exceptional post-purchase assistance. Our helpful and amiable staff is always here to help, whether you have technical inquiries, installation assistance, or maintenance guidance. We are dedicated to creating enduring alliances founded on dependability and trust.

- Competitive Pricing and Value: In our opinion, premium goods shouldn’t be prohibitively expensive. We make sure you receive the maximum return on your investment by offering our top pinch type solenoid valves at competitive pricing. Our goal is to offer affordable solutions that enhance the general productivity and profitability of your business.

- On-time Delivery: We are aware of the financial consequences of delays. Our effective logistics and inventory management systems are made to guarantee prompt order processing and on-time delivery. We put a lot of effort into getting your products to you when you need them so that business can go on as usual.

- Competitive Price and Value: We think that excellent quality ought to be within reach. We strive to provide our high-quality pinch type solenoid valves at affordable costs. Our goal is to provide you the best return on your investment, so you may acquire a high-quality product without going over budget.

Applications of Pinch Type Solenoid Valves

1. Pharmaceutical Industry

- In pharmaceutical manufacturing, hygiene and precision are critical. Pinch valves are perfect for controlling the flow of chemicals, powders, and liquids without contamination. Their ability to handle aggressive and sterile fluids makes them essential in tablet coating, liquid transfer, and filtration processes.

2. Food and Beverage Industry

- The food industry demands valves that are sanitary and resistant to corrosion. Pinch type solenoid valves are widely used in beverages, dairy, and liquid food processing. They help in controlling pasteurization fluids, syrups, juices, and dairy products efficiently, ensuring hygiene and safety standards.

3. Chemical Industry

- Handling corrosive chemicals or abrasive slurries can be challenging with conventional valves. Pinch valves are resistant to chemicals and can manage highly abrasive fluids without damage. They are widely used in chemical dosing, mixing, and transferring operations.

4. Water Treatment Plants

- Water treatment systems require precise flow control for dosing chemicals like chlorine or coagulants. Pinch type solenoid valves offer reliability and minimal maintenance in such continuous operations. They are also effective in controlling wastewater, sludge, and slurry.

5. Mining and Mineral Processing

- Mining operations deal with slurries and abrasive liquids that can quickly wear down traditional valves. Pinch valves offer durability and long service life in such harsh environments. They are used in tailing pipelines, slurry transfer, and abrasive media control.

6. Textile Industry

- Textile processing involves handling dyes and chemical solutions, which require reliable flow control. Pinch valves are perfect for dye transfer, chemical dosing, and liquid handling processes in textile manufacturing.

Table of Specifications Pinch Type Solenoid Valves

| Specification | Details |

|---|---|

| Valve Type | Pinch Type Solenoid Valve |

| Material of Body | Stainless Steel / PVC / Aluminum |

| Tube Material | EPDM, PVC, Silicone |

| Operating Pressure | 0 – 10 Bar |

| Temperature Range | -10°C to 80°C (depending on tube material) |

| Voltage Options | 12V DC, 24V DC, 110V AC, 220V AC |

| Connection Type | Flanged / Threaded |

| Actuation | Electric Solenoid |

| Port Size | 1/2″ – 4″ |

| Applications | Water treatment, chemical industry, food & beverage, pharmaceuticals, mining |

Benefits of Pinch Type Solenoid Valves

- Contamination-Free Operation: The mechanical parts of the valve have no chance of contaminating the media because the fluid only ever comes into contact with the inside of the flexible tube. For sectors where purity cannot be compromised, such as pharmaceuticals, food & beverage, and medical devices, this is essential.

- Managing Difficult Media: Traditional valves can be severely damaged by abrasive slurries, viscous fluids, and liquids containing suspended solids, which can lead to internal component wear and tear. However, these compounds are easily handled by a pinch valve. Particle energy is absorbed by the flexible tubing, and obstructions and accumulation are avoided by the full-bore design.

- Flexible tubing is the single wearing part and requires little maintenance and downtime. When replacement is necessary, the procedure is quick and easy, significantly cutting down on maintenance expenses and time. A major benefit for high-cycle applications is this.

- Pinch valves provide precise control over the flow rate, and the solenoid’s quick on/off switching enables extremely precise dosing and dispensing. Applications such as medication dispensing and diagnostic equipment require this.

- No Dead Volume: Fluid can get stuck in tiny spaces in a lot of valves, which can cause contamination or uneven performance. Due to their unhindered flow channel and lack of “dead volume,” pinch valves guarantee that every last drop of fluid is transferred effectively.

- Easy and Economical Maintenance: The flexible tube can be readily replaced without removing the complete valve from the pipeline when it ultimately wears out. In the long term, this makes them a very practical and cost-effective solution because it lowers labor expenses and downtime.

- Hygienic and Simple to Clean: Pinch valves are simple to clean and sterilize due to their smooth, unhindered flow route and small number of parts, which is crucial for sectors with high hygiene requirements.

Types of Pinch Type Solenoid Valves

1. Direct Acting Pinch Valve

- Direct acting pinch valves operate directly using solenoid force. These are ideal for low flow rates and applications where quick response time is critical.

2. Pilot Operated Pinch Valve

- Pilot operated pinch valves use a small solenoid to control a pilot mechanism, which then opens or closes the main valve. They are suitable for higher flow rates and pressures.

3. 2-Way Pinch Valve

- A simple on off valve that controls the flow in one direction. It is commonly used in process industries, water treatment plants, and chemical industries.

4. 3-Way Pinch Valve

- A three-way pinch valve can divert the flow between two different channels. It is widely used in batching systems, mixing applications, and industrial automation setups.

5. Normally Open Normally Closed Valves

- Pinch valves are available in both normally open and normally closed configurations, giving industries flexibility in designing control systems.

Conclusion

Pinch-type solenoid valves are an example of how intricate issues can be resolved with straightforward, ingenious design. They provide a dependable, low-maintenance, and contamination-free solution for a variety of sectors by separating the fluid and reducing the number of moving parts. We are the best Best Pinch Type Solenoid Valve Dealer.

Keep in mind the value of a reliable partner when you’re prepared to start a new project or improve your system. Ammar Industrial Corporation is prepared to be that partner by offering you the finest pinch-type solenoid valves available along with the knowledgeable assistance you require to guarantee the seamless and effective running of your business. To find out more about our offerings and how we can support the success of your company, get in touch with us right now.