Rodless Cylinder Dealer in Kolkata

Introduction

Established in 2005, Ammar Industrial Corporation is an authorized supplier, wholesaler, dealer, stockist, distributor, and retailer of precision-engineered pneumatic-hydraulic-instrumentation-automation products and industrial process equipment based in Kolkata. Our range includes Air Preparation Unit, Pneumatic Solenoid Valve, Pneumatic Cylinder Actuator, hydraulic tools, fluid automation solenoid valves, etc. Our quality norms enable us to maintain and enhance our position in today’s competitive market. Ammar Industrial Corporation’s premium quality products are recognized as the most reliable firm. Moreover, we follow a quality policy to monitor these products before delivering them to customers.

Kolkata, a thriving center of innovation and industry, is always looking for methods to increase productivity, maximize available space, and improve efficiency. It is impossible to overestimate the importance of sophisticated automation components in this dynamic environment. Among these, rodless cylinders are revolutionary because they provide a special fusion of strength, accuracy, and compact design. You’ve arrived to the correct spot if you’re trying to find a trustworthy rodless cylinder dealer in Kolkata. Leading the way in providing these innovative solutions to companies around the area is Ammar Industrial Corporation. We are the best Rodless Cylinder Supplier.

What Exactly is a Rodless Cylinder

It’s useful to know how a rodless cylinder differs from conventional pneumatic or hydraulic cylinders in order to fully appreciate its worth. Consider a typical cylinder, which contains a rod that can be extended and retracted, hence increasing the amount of room needed to operate. In applications where space is limited, this might be a major drawback. As the name implies, a rodless cylinder does away with this external rod. Rather, the cylinder’s internal piston is attached to an exterior slider or carriage. Most frequently, a variety of clever methods can be used to establish this relationship. We are the best Rodless Cylinder Provider.

Why Choose Ammar Industrial Corporation

- Expertise and Experience: Having worked in the field for almost 20 years, we have extensive expertise and comprehension of pneumatic systems and their uses. Taking into account variables like load magnitude, orientation, stroke length, and cycle rate, our staff can offer professional advice to assist you in choosing the best rodless cylinder for your unique requirements.

- Extensive Product Selection: To meet a range of industrial needs, we provide a large selection of rodless cylinders, including both mechanically and magnetically connected models. We deal in well-known brands, such as SMC Pneumatics, a world leader in pneumatic technology, of which we are an authorized distributor, dealer, agent, and stockist. This guarantees that you will get the best and most dependable products.

- Assurance of Quality: Ammar Industrial Corporation places a high priority on quality. We make sure that every rodless cylinder we sell satisfies strict quality standards by sourcing our products from reputable and well-known suppliers. Before delivery, we carry out thorough inspections to ensure longevity, effectiveness, and durability.

- Customer-Centric Approach: We are committed to establishing enduring bonds with our customers. Our dedication to client satisfaction is demonstrated by our timely service, knowledgeable support, and readiness to offer tailored solutions when required. We receive positive feedback from many of our clients regarding our “good service instant solutions and friendly and patient assistance.

- One-Stop Solution: Ammar Industrial Corporation provides a wide range of industrial process, hydraulic, and pneumatic equipment in addition to rodless cylinders. For all of your industrial automation requirements, including fittings, hoses, solenoid valves, air preparation units, and more, we are a handy one-stop shop.

- Dependable After-Sales Support: We provide thorough after-sales services to guarantee your systems run smoothly and effectively in addition to selling products. What distinguishes us is our dedication to continuous support.

- Competitive Pricing: We work hard to provide our products at affordable and competitive prices, guaranteeing that you receive the best return on your investment, without sacrificing quality.

Applications of Rodless Cylinder

- Material handling and logistics: Rodless cylinders are ideal for accurately and efficiently moving goods, whether they are being moved along conveyor belts or stored and retrieved automatically. Consider automated warehouses where items must be transported over long distances in a constrained amount of space.

- Packaging Equipment: Rodless cylinders are utilized in packaging lines for opening and shutting flaps, putting objects into boxes, and placing goods for wrapping. For large-scale manufacturing, their accuracy and speed are essential.

- Assembly Lines: Rodless cylinders are essential for precisely positioning components during assembly in the automotive, electronics, and other production industries. Their precise motion is essential for tasks like installing tiny electrical components or pushing car doors into position.

- Textile Industry: Rodless cylinders can be used in textile machinery to guide fabric, adjust tension, and operate cutting mechanisms, all of which help to produce goods more quickly and accurately.

- Printing and Labeling: These cylinders ensure steady and efficient operation by assisting in the movement of paper, labels, or other materials through printing and labeling equipment.

- Clean Room Environments: Because of its completely sealed construction, magnetically connected rodless cylinders are ideal for sectors where contamination is strictly prohibited, such as food processing, semiconductors, and pharmaceuticals.

- Robotics: As the use of robots in manufacturing increases, rodless cylinders are essential for giving robotic arms and end-effectors linear motion, which improves their reach and dexterity.

- Machine Tooling: Rodless cylinders are used in a variety of machine tools to precisely place workpieces or tools, improving the final product’s accuracy and quality.

Specifications Table of Rodless Cylinder

| Parameter | Specification |

|---|---|

| Cylinder Type | Rodless Cylinder |

| Bore Size (mm) | 16, 25, 32, 40, 50, 63 |

| Stroke Length | Up to 6000 mm |

| Working Pressure Range | 1.5 – 8.0 bar |

| Operating Medium | Filtered, lubricated or non-lubricated air |

| Maximum Speed | 500 – 1500 mm/s |

| Temperature Range | -20°C to +80°C |

| Cushioning | Pneumatic or mechanical |

| Mounting Options | Foot, flange, trunnion, side |

| Materials | Aluminium alloy body, stainless steel piston rod |

| Sealing | NBR / FKM for high-temperature options |

| Magnetic Sensor Compatibility | Available on request |

Benefits of Rodless Cylinders

- The biggest advantage is Space Optimization Rodless cylinders enable significantly more compact machine designs in factories where every inch counts. This implies that you can save a significant amount of money on real estate by expanding your production line’s footprint or even reducing its overall size. The benefit of rodless cylinders is that they can fit a longer stroke into a smaller space.

- Longer Stroke Lengths without Rod Buckling: Rodless cylinders can produce noticeably longer strokes without the risk of rod buckling or bending under strong loads, which is a concern with traditional cylinders. The force is distributed more efficiently because the cylinder body supports the load directly. They are therefore ideal for uses like material transfer over a production line that call for long linear travel.

- Enhanced Safety: There is a much lower chance of unintentional harm from moving parts because there is no external rod that can extend or retract. Your operators will work in a safer atmosphere as a result.

- Decreased Side Loading and Wear: Rodless cylinders naturally have less side loading on the piston since the load is directly borne by the carriage moving along the cylinder body. As a result, internal components experience less wear and tear, extending their lives and requiring less maintenance.

- Versatility in Application: Rodless cylinders are incredibly versatile and can be used in a wide range of applications, including pick-and-place and material handling systems, packaging equipment, automated assembly lines, and even the printing and textile industries. They are flexible enough to meet a range of industrial demands due to their capacity to manage different loads and speeds. Because of their sealed design, magnetically coupled versions are especially well-suited for cleanroom settings, like those found in food processing or pharmaceuticals.

- Better Aesthetics and System Integration: Cleaner, more efficient machine designs are frequently the result of rodless cylinders’ small, enclosed construction. In addition to improving appearance, this makes integrating into intricate automation systems easier.

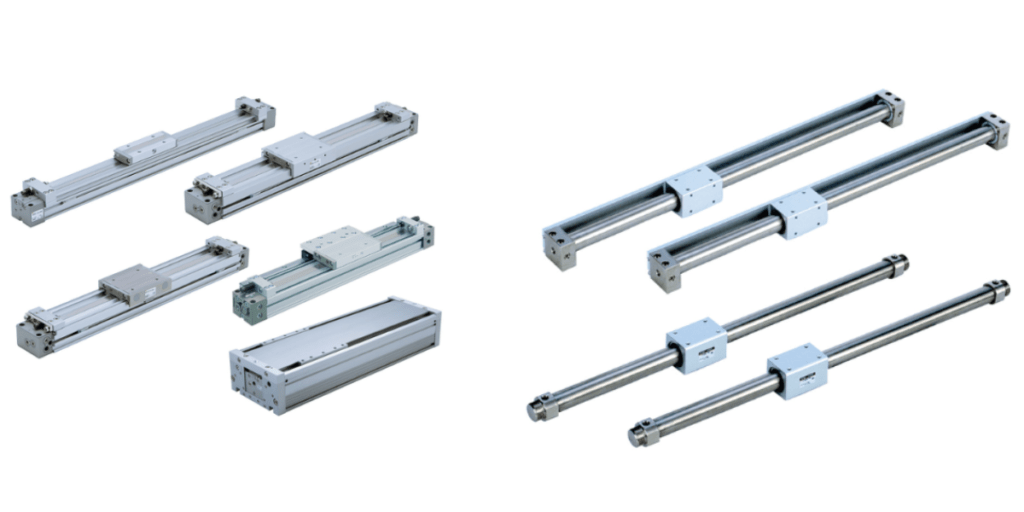

Types of Rodless Cylinders

1. Band-Type Rodless Cylinders (Sealing Band Cylinders)

- These are the most commonly used rodless cylinders. A piston moves inside a sealed barrel, and the load is mounted on a carriage that is magnetically or mechanically connected to the piston. A flexible sealing band keeps the barrel airtight.

Best For: Packaging machines, textile machines, material handling systems.

2. Cable-Type Rodless Cylinders

- In this type, a cable or wire connects the piston to the external carriage. As the piston moves inside the cylinder, the cable moves the load outside.

Best For: Applications with irregular load paths or where linear motion needs to follow a curved path.

3. Magnetically Coupled Rodless Cylinders

- These use powerful magnets to connect the piston and the carriage. The piston inside moves via compressed air, and the carriage follows the piston outside due to magnetic force.

Best For: Cleanroom applications, sensitive environments (since the piston is sealed inside and doesn’t breach the outer shell).

4. Belt-Driven Rodless Actuators

- These are electromechanical devices where the motion is driven by a motor connected to a belt, rather than compressed air. They are ideal for high-speed or heavy-duty automation systems.

Best For: CNC machines, robotic arms, printing systems.

Conclusion

A major development in linear motion technology, rodless cylinders provide unmatched space efficiency, longer strokes, improved stability, and lower maintenance. Purchasing these cutting-edge pneumatic solutions is a wise strategic choice for Kolkata firms hoping to streamline their processes and adopt cutting-edge automation. We are the best Best Rodless Cylinder Dealer.

We invite you to discover the Ammar Industrial Corporation difference, whether your goal is to create a new automated solution or upgrade an existing system. We are the perfect partner for all of your pneumatic and industrial automation needs in Kolkata because of our experience, wide selection of products, and unshakable dedication to your success.