2/2 Way Direct Acting Valve Dealer

Introduction

Established in 2005, Ammar Industrial Corporation is an authorized supplier, wholesaler, dealer, stockist, distributor, and retailer of precision-engineered pneumatic-hydraulic-instrumentation-automation products and industrial process equipment based in Kolkata. Our range includes Air Preparation Unit, Pneumatic Solenoid Valve, Pneumatic Cylinder Actuator, hydraulic tools, fluid automation solenoid valves, etc. Our quality norms enable us to maintain and enhance our position in today’s competitive market. Ammar Industrial Corporation’s premium quality products are recognized as the most reliable firm. Moreover, we follow a quality policy to monitor these products before delivering them to customers.

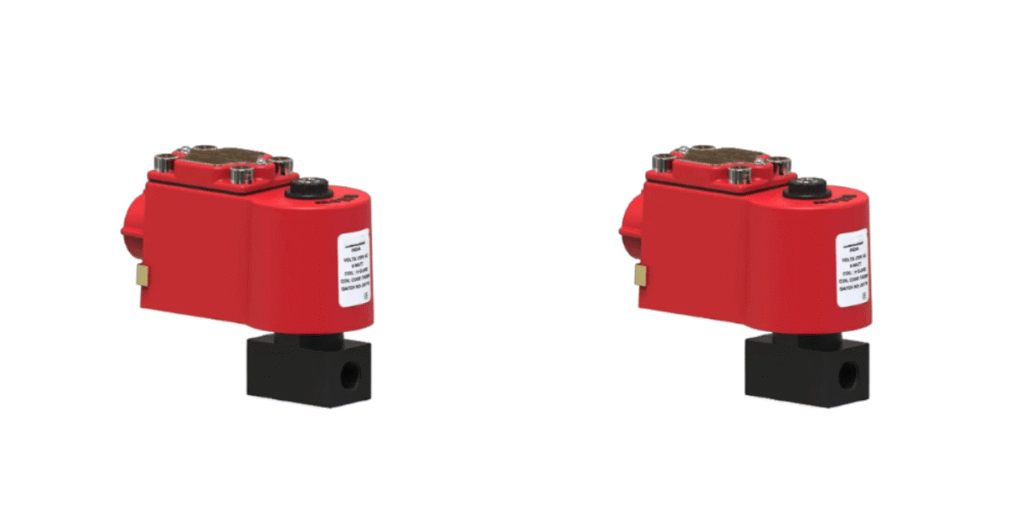

In many sectors where it is necessary to manage liquids, gasses, and other media, valves are crucial. Due to its straightforward design, dependable operation, and adaptability for a wide range of industrial applications, the 2/2 Way Direct Acting Valve has become one of the most widely used valve types. Ammar Industrial Corporation, a well-known brand in industrial supplies and solutions, is the answer to your search for a reliable 2/2 Way Direct Acting Valve Dealer.The definition of a 2/2 Way Direct Acting Valve, its operation, advantages, uses, and the reasons Ammar Industrial Corporation is the best partner for your needs will all be covered in this article. We are the best 2/2 Way Direct Acting Valve Supplier.

What is a 2/2 Way Direct Acting Valve

To put it simply, a solenoid valve is a 2/2 way direct acting valve. Having two ports an input and an outlet and two switching positions open and closed is what the term 2/2 way refers to. Direct acting describes its straightforward and efficient operation: the magnetic force of an energized coil directly controls the plunger of the valve, which serves as the sealing element. This is an important difference from pilot operated valves, which open and close with the help of medium pressure. We are the best 2/2 Way Direct Acting Valve Provider.

Why Choose Ammar Industrial Corporation

- Unwavering Dedication to Quality: Quality is more than simply a catchphrase at Ammar Industrial Corporation. It serves as the cornerstone of our company. We only purchase our goods from reliable producers, and each one is put through a rigorous quality inspection process before being sent to you. This dedication guarantees that the valves you get from us are robust, effective, and will function dependably even in the most taxing circumstances.

- Reliability in Quality: Ammar Industrial Corporation is dedicated to offering only the best products. Our 2/2 way direct acting valves are sourced from reputable manufacturers, ensuring dependability, longevity, and steady performance even in the most taxing conditions. Our emphasis on quality has established us as a reputable and well-known brand in the industry.

- Broad Product Offering:and Technical Know-How We provide a large range of fluid automation products, including a large assortment of 2/2-way direct acting valves in various sizes, shapes, and materials. Our staff is prepared to offer professional technical support and has a wealth of product expertise. We can help you find the ideal product, whether you require a basic solution or one that is tailored for a particular purpose.

- Dependable Pan-India Distribution: We can service customers all throughout India because to our strong and effective distribution network, which is based in Kolkata. Our efficient logistics guarantee prompt order processing and on-time delivery, reducing downtime for your business. We recognize that time is money.

- Customer-Centric Approach: Prioritizing our customers is the foundation of our company. We are committed to offering practical answers that assist you in recognizing your issues and obtaining the appropriate product. Our staff is dedicated to offering a hassle-free and encouraging experience from pre-sales consulting to after-sales care.

- Expert Support and Knowledge: Our staff is made up of experienced experts that are committed to assisting you in locating the ideal answer. In order to maximize performance and efficiency, we provide technical support and knowledgeable guidance to help you choose the best valve for your application.

- Technical Support & Expertise: With years of experience, our team of committed professionals is always available to offer you knowledgeable guidance. We provide outstanding after-sales assistance and assist you in selecting the ideal valve for your application.

- On-time and Reliable Delivery: We know that time is money. Your orders will be delivered promptly and on time thanks to our well-maintained supply network, keeping your projects on track.

- Vast Stock & Quick Availability: With our well-located facility in Ghaziabad, we have a large stock of different coil voltages, materials, and valve designs. This reduces downtime and keeps your projects on track by giving you quicker access to the premium components you require. We are aware that time is money in the business world.

- Competitive Value: We recognize the significance of cost-effectiveness while also placing a high priority on quality and performance. We are able to provide reasonable pricing because of our solid ties with manufacturers, which guarantees that you will receive the most return on your investment in high-performance components.

Applications of 2/2 Way Direct Acting Valves

1. Water Treatment Plants

- Direct acting valves help regulate water flow, control chemical dosing, and manage filtration systems effectively.

2. Oil & Gas Industry

- They are widely used in controlling gas flow, managing oil transfer systems, and ensuring safety in pipelines.

3. Pharmaceutical Industry

- In pharmaceutical manufacturing, hygiene and precision are critical. These valves control the flow of liquids and gases in cleanroom environments with high accuracy.

4. Food & Beverage Industry

- From processing milk and juices to controlling steam in food packaging, direct acting valves ensure hygiene and efficiency.

5. HVAC Systems

- Heating, ventilation, and air-conditioning systems rely on these valves to regulate water and refrigerant flow.

6. Chemical Industry

- Direct acting valves are essential for handling corrosive fluids, acids, and alkalis safely.

7. Power Plants

- They are used to manage steam and cooling systems for uninterrupted power generation.

8. Irrigation Systems

- In agriculture, these valves are used in automated irrigation systems to regulate water supply efficiently.

Table of Specifications 2/2 Way Direct Acting Valve

| Parameter | Specification |

|---|---|

| Valve Type | 2/2 Way Direct Acting Valve |

| Port Size | 1/8” to 2” (Custom sizes available) |

| Operation | Normally Closed (NC) / Normally Open (NO) |

| Body Material | Brass / Stainless Steel / Engineering Plastic |

| Seal Material | NBR, EPDM, Viton |

| Pressure Range | 0 – 10 bar (depends on model) |

| Temperature Range | -10°C to +80°C (higher ranges on request) |

| Voltage Options | 12V DC, 24V DC, 24V AC, 110V AC, 230V AC |

| Coil Protection | IP65 / Weatherproof |

| Media | Air, Water, Oil, Steam, Gas, Chemicals |

| Mounting Position | Any (Horizontal/Vertical) |

| Flow Range | Based on port size and orifice diameter |

Benefits of 2/2 Way Direct-Acting Valves

- Quick Reaction: There is no delay as pilot pressure builds up since the solenoid moves the plunger directly. This leads to incredibly quick opening and shutting times, which are essential for applications like high-speed automation or dispensing systems that need precise and instantaneous fluid management.

- Zero Pressure Operation: This is perhaps their most significant benefit. Unlike many other solenoid valves, direct-acting valves do not require a minimum pressure differential between the inlet and outlet to function. They work flawlessly even when there’s no pressure or under vacuum conditions, making them ideal for systems that start from zero pressure or handle very low flow rates.

- Simplicity and Reliability: Direct-acting valves are mechanically simpler than pilot-operated valves because they have fewer moving parts. This results in a longer operational lifespan, reduced maintenance needs, and increased reliability. There are fewer points of failure when there is less complexity.

- Compact Design: Smaller, more compact valve bodies are made possible by their simple design. When space is limited, as in the case of small equipment, complex control panels, or portable devices, this is a significant benefit.

- Versatility: These valves are used in a wide range of sectors to control everything from air and inert gases to water, light oils, and even harsh chemicals if the right materials are chosen.

- Lightning-Quick Response Time: These valves are able to open and close with remarkable speed because of the direct mechanical connection between the solenoid’s magnetic force and the plunger’s movement. Applications requiring high-frequency cycling and exact timing depend on this quick reaction.

- Unmatched Durability and Reliability: Direct-acting valves are naturally less prone to wear and tear because they have fewer moving parts and a sturdy design. Better dependability, longer operational lifespans, and less maintenance needs result from this, which lowers overall operating expenses.

- Compact and Space-Efficient Design: Because of their simple design, they have a comparatively small footprint, which makes them ideal for integration into small areas or miniature systems where every millimeter matters.

- fine Flow Control: Although these devices are mostly ON/OFF, their fast action enables fine control over the fluid flow duration, which can be crucial in batching or dosing applications.

Types of 2/2 Way Direct Acting Valves

1. Normally Closed NC Valves

- In this type, the valve remains closed when there is no power supply.

- As soon as electrical current is applied, the solenoid opens the valve to allow fluid flow.

- Commonly used for safety applications where the default condition should be “no flow.”

2. Normally Open NO Valves

- In this type, the valve remains open without power and closes when electrical current is applied.

- Used in systems where continuous flow is required unless actively stopped.

- Ideal for applications such as cooling circuits.

3. Miniature Direct Acting Valves

- Small-sized valves designed for compact systems or low-flow applications.

- Commonly used in medical devices, laboratory instruments, and small-scale automation.

4. High-Pressure Direct Acting Valves

- Designed to handle high-pressure fluids and gases.

- Built with strong materials and seals to withstand demanding industrial environments.

- Often used in hydraulic systems and compressed air applications.

5. Stainless Steel Direct Acting Valves

- Made from corrosion-resistant stainless steel for handling aggressive or corrosive fluids.

- Ideal for industries like chemical processing, pharmaceuticals, and food & beverage.

Conclusion

Ultimately, the 2/2 way direct-acting solenoid valve is a potent illustration of how basic engineering may produce significant outcomes. It is essential in many contemporary systems because it can quickly, precisely, and reliably control fluid flow in a small, zero-pressure setting. This valve is a little but powerful part that guarantees effectiveness and safety in anything from the complex machinery of a medical device to the extensive automation of a factory floor.

Go no farther than Ammar Industrial Corporation if your company requires these essential elements. We are the perfect partner for all of your industrial automation and fluid control needs because of our long history of expertise, dedication to quality, and emphasis on creating enduring connections with our clients.