3/2 Way Direct Acting Valve Dealer

Introduction

Established in 2005, Ammar Industrial Corporation is an authorized supplier, wholesaler, dealer, stockist, distributor, and retailer of precision-engineered pneumatic-hydraulic-instrumentation-automation products and industrial process equipment based in Kolkata. Our range includes Air Preparation Unit, Pneumatic Solenoid Valve, Pneumatic Cylinder Actuator, hydraulic tools, fluid automation solenoid valves, etc. Our quality norms enable us to maintain and enhance our position in today’s competitive market. Ammar Industrial Corporation’s premium quality products are recognized as the most reliable firm. Moreover, we follow a quality policy to monitor these products before delivering them to customers.

In the realm of fluid control and industrial automation, valves are essential to maintaining efficient operations. The 3/2 Way Direct Acting Valve is one of the most often used valve types due to its effectiveness, robustness, and user-friendliness. Ammar Industrial Corporation is the place to go if you’re searching for a reliable 3/2 Way Direct Acting Valve Dealer. Delivering premium valves that satisfy global standards and cater to a variety of sectors is our area of expertise.This post will describe a 3/2 way direct acting valve, including its functions, uses, advantages, and why picking Ammar Industrial Corporation as your dealer guarantees dependability and efficiency. We are the best 3/2 Way Direct Acting Valve Supplier.

What is a 3/2 Way Direct Acting Valve

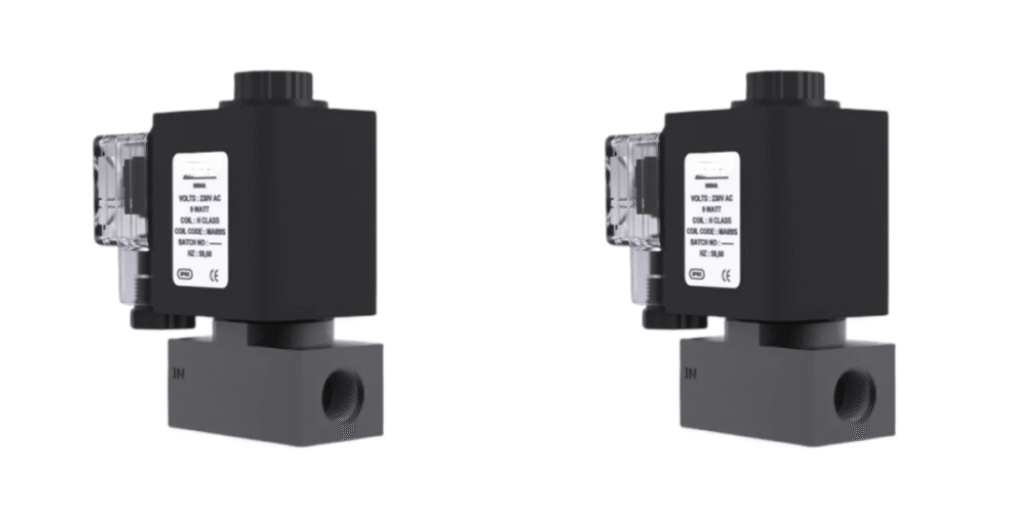

A 3/2-way valve is essentially a directional control valve with two switching positions and three ports. Usually, these ports are an exhaust, an outlet, and an intake. By alternating between these two states, the valve regulates the flow of a fluid such as air, gas, or liquid.The phrase direct-acting describes how it functions. A direct-acting valve use an electromagnetic coil to move an internal component known as an armature or plunger directly, in contrast to other valves that would need a pressure differential to operate. Because of its straightforward design, it can function even in vacuum or with zero pressure, which is a big plus in a lot of applications. We are the best 3/2 Way Direct Acting Valve Provider.

Why Choose Ammar Industrial Corporation

- Unmatched Expertise: The members of our team are seasoned experts with extensive backgrounds in industrial automation and solenoid valve technology. Whether you’re working with gas, oil, water, or air, we can help you choose the best valve for your particular application. To help you make the best choice possible, we offer comprehensive specifications and suggestions.

- Broad and Varied Product Selection: We provide a large assortment of 3/2 way direct-acting valves from top producers. Various body materials, such as brass and stainless steel, various seal materials for chemical compatibility, and a range of voltage options are all part of our assortment. We have a solution that meets your system’s needs, whether they are for a small, low-power setup or a high pressure application.

- Dedication to Quality: We place a high premium on quality. We purchase our valves from reliable suppliers that are renowned for their long-lasting designs and strict quality control. Our valves are long-lasting, reducing downtime and ultimately saving you money.

- Customer-Focused Service: We are committed to establishing enduring bonds with our customers. From initial questions to post-purchase assistance, our committed support staff is always here to help. Our strong logistics and inventory management systems guarantee that your shipments are always delivered on schedule.

- Technical support and expertise: Our staff offers solutions rather than just items. We can assist you in choosing the ideal valve for your application because we possess the technical know-how. To guarantee a seamless, trouble-free experience, we also provide after-sales support.

- Extensive Stock: We have a sizable inventory of fittings, cylinders, valves, and other industrial parts for fluid automation. As a result, we can promptly complete your orders, reducing downtime and ensuring that your projects are completed on time.

- Competitive Pricing: We’re dedicated to providing the greatest goods at the most affordable costs. We can pass the savings on to you without sacrificing quality by optimizing our supply chain and concentrating on efficiency. You receive premium goods without having to pay a premium price.

- Customer-Centric Approach: We put your happiness first. You may acquire the parts you require when you need them thanks to our prompt and dependable delivery throughout India. We also provide customization choices to satisfy the particular needs of your project. Our helpful customer support staff is always here to help.

- A Wide Variety of Products:To satisfy the unique requirements of any application, we provide a wide range of 3/2 way direct-acting valves. In order to manage a variety of media, from air and water to corrosive chemicals and steam, our collection comprises valves made of brass, stainless steel, and aluminum, as well as numerous seal materials. We offer the ideal option, whether you require a sturdy valve for a high-pressure industrial system or a tiny one for a delicate medical device.

Applications of 3/2 Way Direct Acting Valves

1. Pneumatic Systems

- Widely used in compressed air systems to control cylinders and actuators.

- Helps in starting, stopping, or changing the direction of air flow.

2. Water and Fluid Control

- Ideal for controlling water supply in industrial plants.

- Used in washing systems, cooling systems, and irrigation units.

3. Oil and Gas Industry

- Plays a role in lubrication systems and hydraulic units.

- Suitable for handling neutral gases, light oils, and process fluids.

4. Medical and Laboratory Equipment

- Used in oxygen supply systems, gas analyzers, and diagnostic devices.

- Ensures precise flow control in delicate applications.

5. Food and Beverage Industry

- Controls the flow of water, carbon dioxide, and other fluids in bottling, brewing, and packaging plants.

6. Automotive Industry

- Used in fuel handling systems, washing stations, and pneumatic tools.

7. HVAC Systems

- Applied in heating, ventilation, and cooling systems for regulating air and water flow.

Table Specifications of 3/2 Way Direct Acting Valve

| Parameter | Specification |

|---|---|

| Material | 3/2 Way Direct Acting Valve |

| Operation | Solenoid / Mechanical |

| Port Size | 1/8” to 1” (custom sizes available) |

| Body Material | Brass / Stainless Steel / Aluminium |

| Seal Material | NBR, EPDM, FKM |

| Pressure Range | 0 – 10 bar |

| Temperature Range | -10°C to +80°C (depending on seal type) |

| Medium | Air, Water, Oil, Inert Gases |

| Mounting | Inline / Manifold |

| Voltage Options | 12V DC, 24V DC, 110V AC, 230V AC |

| Response Time | Less than 20 ms |

Benefits of 3/2 Way Direct Acting Valve

- Perhaps the greatest benefit is that there is no minimum pressure needed. Direct-acting valves can function with little to no pressure, in contrast to pilot-operated valves that require a specific pressure differential to function. They are hence ideal for low-pressure systems, vacuum applications, and circumstances with fluctuating pressure.

- Compact and Cost-Effective: They have a smaller, more compact footprint thanks to their straightforward design. In addition to saving room in congested industrial settings, this also lowers the cost of production and acquisition.

- Fast Response Time: A quick opening and shutting action is guaranteed by the plunger’s direct movement. This is essential for applications like dosing or filling machines that need exact timing and instant fluid control.

- Quick Response Time: These valves can change positions nearly instantaneously due to their direct acting nature. This is essential for applications like robotic arms, sorting systems, and packing machinery that need precise, fast movements. Productivity can rise significantly with just one millisecond saved.

- Compact and Space-Saving Design: These valves are usually quite small and light because of their simple design. This makes them perfect for use in portable or small equipment and for integrating into confined spaces.

- High Durability and Reliability: There are fewer moving parts, so there are less potential problems than with a pilot-operated valve. Your operations will have a longer lifespan, require less maintenance, and have less downtime as a result. They are designed to endure the harsh conditions found in industrial settings.

- Low Power Consumption: In systems with several valves, the direct acting design frequently uses less power to run the solenoid, which can result in energy savings.

- Versatility: Although we’ve only discussed compressed air, these valves may also regulate the flow of other gases and even some liquids, which makes them suitable for a variety of uses, including chemical processes and medical equipment.

- Compact and Lightweight Design: Compared to many other valve types, they are smaller and lighter due to their straightforward design. This is especially helpful for portable equipment or systems with limited space.

Types of 3/2 Way Direct Acting Valves

1. Normally Closed NC Valve

- In the resting position, the valve remains closed.

- When energized, the valve opens to allow flow.

- Commonly used for safety purposes where flow must stop during power loss.

2. Normally Open Valve

- In the resting position, the valve remains open.

- When energized, it closes to stop the flow.

- Suitable where continuous flow is required in standby mode.

3. Universal Type Valve

- Can be used as both normally closed and normally open, depending on installation.

- Offers flexibility in system design.

4. Stainless Steel 3/2 Way Direct Acting Valve

- Designed for aggressive fluids, chemicals, and corrosive environments.

- Commonly used in food, chemical, and pharmaceutical industries.

5. High-Pressure 3/2 Way Valve

- Specially built to handle high-pressure applications.

- Ideal for hydraulic systems and industrial machinery.

6. Miniature 3/2 Way Valve

- Compact, lightweight, and easy to integrate into small devices.

- Suitable for laboratory equipment and medical devices.

Conclusion

Because they offer a straightforward yet effective method of controlling fluid flow, 3/2 way direct-acting valves are essential parts of contemporary industrial automation. They are extremely dependable for a variety of applications because to their direct electromagnetic force-based design, particularly in low-pressure and vacuum settings.

Selecting the appropriate valve and dealer is essential. Go no farther than Ammar Industrial Corporation for dependable, superior 3/2 way direct-acting valves and unmatched customer service. We are in a unique position to be your reliable partner for all of your industrial needs because of our wide range of products, technical know-how, and unwavering dedication to client satisfaction.